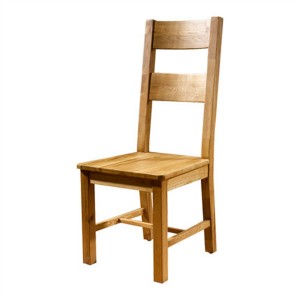

Solid white oak natural dining chair modern

Product Description

It is ergonomically designed and very comfortable to sit. It will eliminate the fatigue of the whole day, and give your dining and leisure life a warm and comfortable coexistence.

This solid wood dining chair is originated high-end design, by crafted with modern craftsmanship, unmatched in texture, detail and workmanship, applying white oak of North America and environmentally friendly and healthy paint, the simple solid wood feeling is vividly displayed! Perfect design layout, exquisite craftsmanship, and dining is also an excellent enjoyment!

Liangmu is a professional manufacturer of mid-to-high-end wood furniture with a long history of 38 years, we can customize environmentally friendly furniture at different prices, materials and specifications to meet your various needs.

Product Specification

| Size | Species | Finishing | function |

| 430*450*870mm | white oak | NC clear lacquer | dining |

| 450*450*870mm | walnut | PU lacquer | study |

| 450*450*850mm | white ash | wood wax oil | living |

| Bent wood | AC lacquer | Children's chair |

This design of this white oak solid wood dining chair, adheres to the principle of "less is more", simplifying complexity, focusing on quality, function and details are advocated a comfortable, elegant and natural life taste, the entire series of products show the spectacular, calm, and a strong sense of value experience.

Product Features

Processing:

Materials preparation→Planing→edge gluing→profiling→drilling→sanding→base primed→top coating→assembly→packaging

Inspection for raw materials:

If the sampling inspection is qualified, fill in the inspection form and send it to the warehouse; Directly return if failed .

Inspection in processing:

Mutual inspection between each process, directly returned to the previous process if failed. During the production process, QC conducts inspections and sampling inspections of each workshop. Apply test assembly of unfinished products to confirm the correct processing and accuracy, then paint afterwards.

Inspection at finishing and packaging:

After parts finished are fully inspected, they are assembled and packaged. Piece by piece inspection before packaging and random inspection after packaging.

File all inspection and modifying documents in record, etc